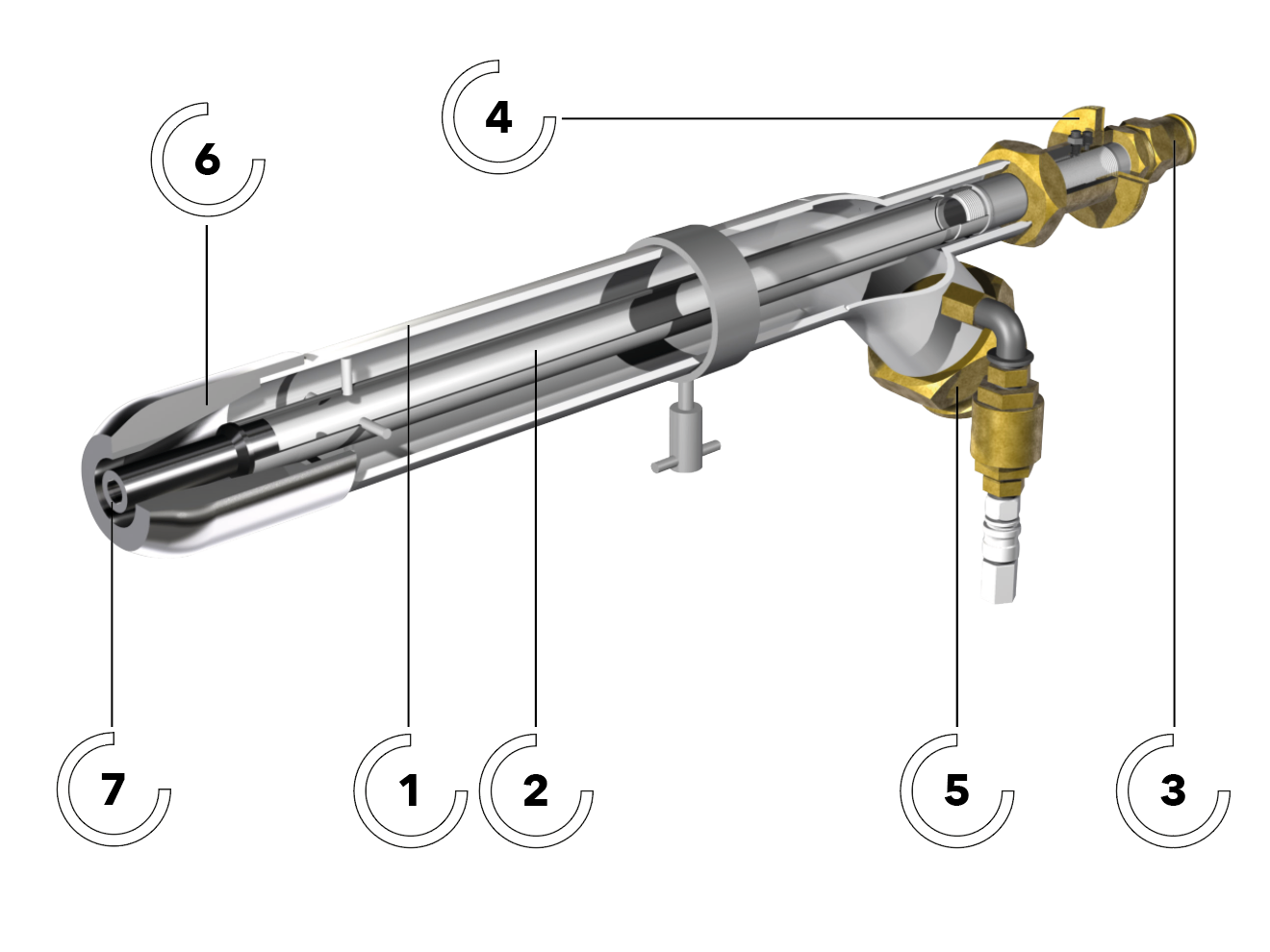

As it is the case with the DUALFLAME MC burner, the DUALFLAME AC (Automatic Control) burner works with two nozzles, an inner and an outer nozzle. The position of the inner nozzle can be controlled by a hand wheel at the rear of the burner in the same way as the DUALFLAME MC. Thus the flame can be shaped from soft and wide to sharp and strong.

The DUALFLAME AC burner, however, works with an automatic control of the gas quantity towards the inner and outer nozzle. Therefore gas control valves for each nozzle are installed in the utility equipment in front of the burner. This enables the furnace operator to adjust the flame length automatically in the control room without manual adjustment directly at the burner under the hot burner port.

Apart from the automatic adjustment of the burner after a load change and/or a change in the gas quantity, the ratio of the gas flow between the inner nozzle and the outer nozzle is maintained exactly constant even when the total gas quantity changes.

Furthermore, all burners can be regulated identically without variations since the gas quantity for the inner and outer nozzle is measured. This results in absolute identical firing conditions in each firing period for both the left and the right burner port(s).

Another advantage of the DUALFLAME AC burner is the laminar gas flow in the inner nozzle which, unlike the DUALFLAME MC burner, is not equipped with openings and mechanical built-in parts. Therefore the laminar outflow of the gas at the nozzle head is guaranteed and will prevent NOx formation.

The adjustable gas velocity can vary e.g. between values of > 20 m/s and < 200 m/s depending on gas admission pressure, gas consumption, gas distribution to each nozzle and the size of the nozzles.

| Model | Gas capacity* | Gas attachment |

| AC 200 | 22 - 220 Nm³/h | DN 50, R2” / DN 25 R1” |

| AC 500 | 55 - 550 Nm³/h | DN 65, R21/2“ / DN 32 R11/4“ |

| AC 700 | 75 - 750 Nm³/h | DN 80, R3“ / DN 50, R2“ |

| AC 1000 | 100 - 1100 Nm³/h | DN 80, R4“ / DN 50, R2“ |

COOKIES

We use cookies to make it easier to use and to further improve our service.

If you have given us your consent, you can revoke it at any time in the data protection declaration.

COOKIES

Necessary

Necessary cookies help make a website usable by enabling basic functions such as page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

C3 Cookie

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| c3kie | hornglass.com | Saves the consent status of the user whether the cookie window should be displayed. | 180 days | HTTP Cookie |

Technical

Technichal cookies help to improve the user experience of the website. New functionalities will be enabled.

YouTube

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| yt-player-headers-readable | YouTube | Used to determine the optimal video quality based on the visitor's device and network settings. | Persistent | HTML Local Storage |

| VISITOR_INFO1_LIVE | YouTube | Tries to estimate the range of users on pages with built-in YouTube videos. | 179 days | HTTP Cookie |

| YSC | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Session | HTTP Cookie |

| yt.innertube::nextId | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Persistent | HTML Local Storage |

| yt.innertube::requests | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Persistent | HTML Local Storage |

| ytidb::LAST_RESULT_ENTRY_KEY | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-cast-available | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-cast-installed | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-connected-devices | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-device-id | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-fast-check-period | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-session-app | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-session-name | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

Advertisement

Advertisement cookies allow our advertising partners to show you ads that fit your interests.

TikTok

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _ttp | TikTok | Used to store a unique user ID. | 1 year | HTTP Cookie |

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _fbp | Used to store and track visits to websites. | 3 months | HTTP Cookie |

Statistics

Statistics cookies help website owners understand how visitors interact with websites by collecting and reporting information anonymously.

Google Tag Manager

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _ga | Google Tag Manager | Registers a unique ID that is used to generate statistical data on how the visitor uses the website. | 2 years | HTTP Cookie |

| _ga_ | Google Tag Manager | Collects data on how often a user visited a website, as well as data on the first and last visit. Used by Google Analytics. | 2 years | HTTP Cookie |

Microsoft Clarity

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _clck | Microsoft | Persists the Clarity User ID and preferences, unique to that site is attributed to the same user ID. | 1 year | HTTP Cookie |

| _clsk | Microsoft | Connects multiple page views by a user into a single Clarity session recording. | 1 year | HTTP Cookie |

| CLID | Microsoft | Identifies the first-time Clarity saw this user on any site using Clarity. | 1 year | HTTP Cookie |

| ANONCHK | Microsoft | Indicates whether MUID is transferred to ANID, a cookie used for advertising. Clarity doesn't use ANID and so this is always set to 0. | 1 year | HTTP Cookie |

| MR | Microsoft | Indicates whether to refresh MUID. | 1 year | HTTP Cookie |

| MUID | Microsoft | Identifies unique web browsers visiting Microsoft sites. These cookies are used for advertising, site analytics, and other operational purposes. | 1 year | HTTP Cookie |

| SM | Microsoft | Used in synchronizing the MUID across Microsoft domains. | 1 year | HTTP Cookie |