The HORN® Hot End Automation System represents the latest development in process automation, which assists the glass plant in the background.

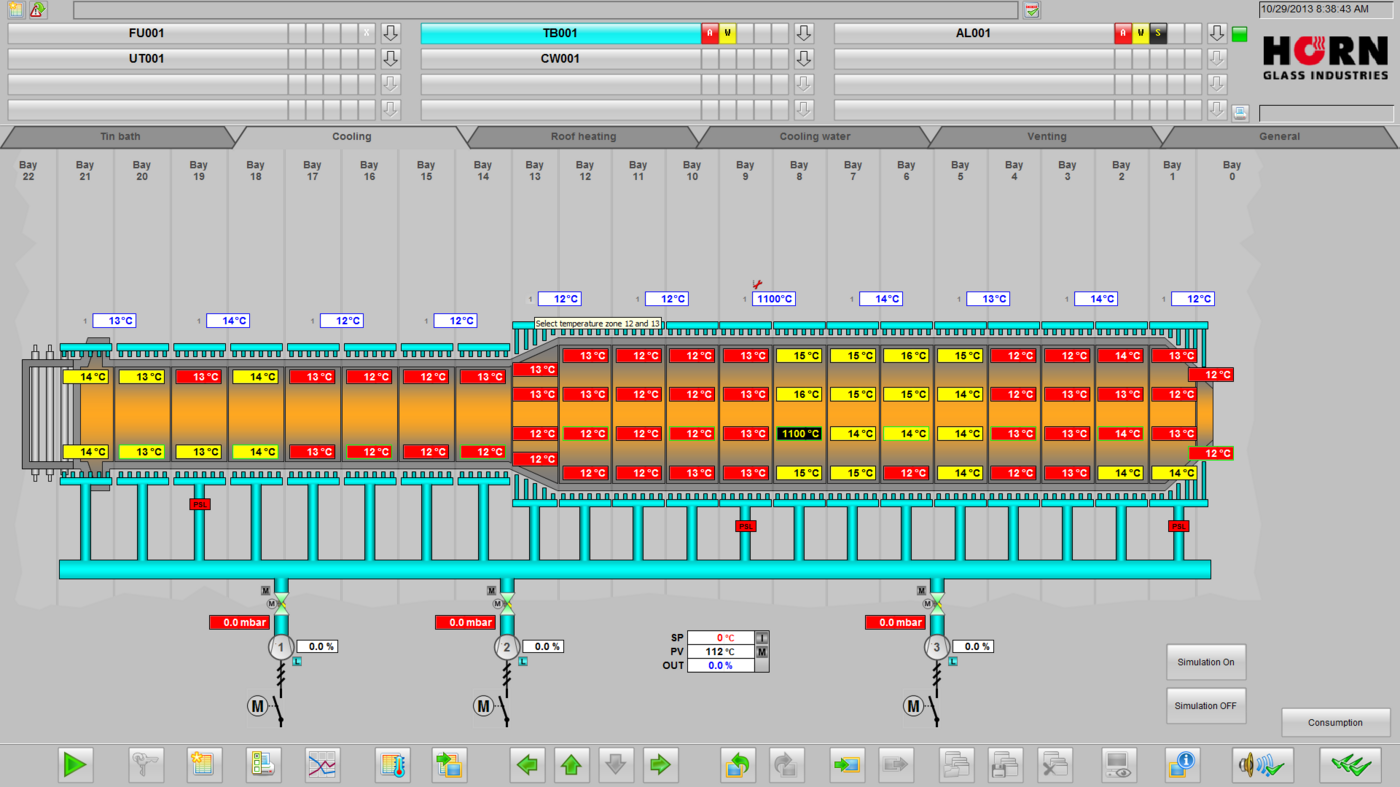

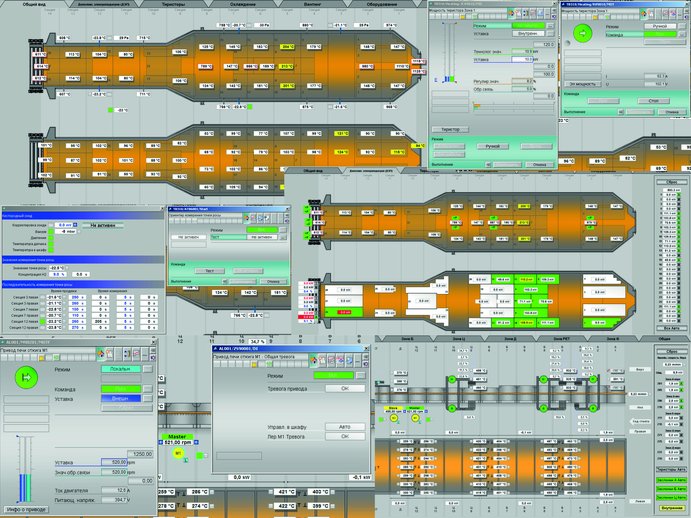

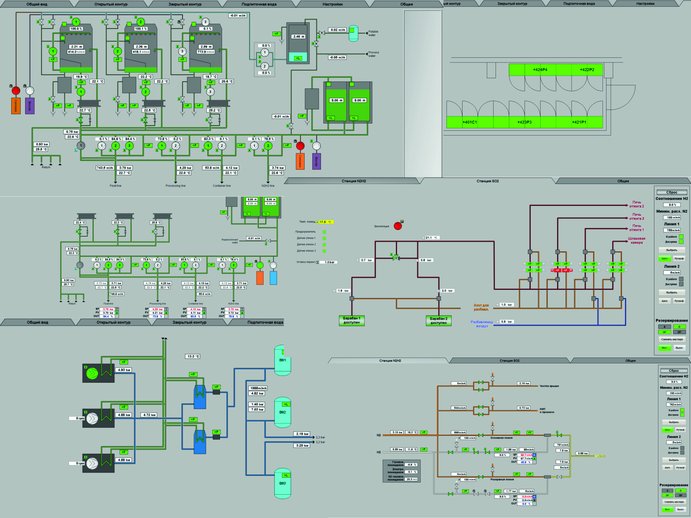

By means of the Hot End Automation System the operating processes at the glass melting furnace, the tin bath and the lehr are effortlessly controlled from one location with only a few mouse clicks.

In the air-conditioned and well-equipped control room, where all necessary control and visualisation components are located, the Hot End Automation System assists in controlling a complex production process. Moreover, the Hot End Automation System coordinates the measurement and control components of the production process to form a fully integrated process control system.

HORN® has put all its knowhow and decades of experience in the field of measurement and control technology into the hardware and software of the Hot End Automation System. As the basis, HORN® uses systems and components from leading system suppliers.

The measuring complex collects data from a system of sensors and sends it to I/O modules.

At this stage the electric signals are processed and transmitted to the higher-level process control system. The programmatical linking of all analogue and digital signals is effected in the automation device. The measured values are processed and scaled for the control complex.

Process integration is managed on three levels. The internal linkage between the levels of the measurement and control complex is executed via bus systems:

The field devices (sensors/actuators) are connected via a field bus system, e.g. Profibus DP, Profinet, CAN bus.

Here the automation and visualisation devices are connected to the higher-level process visualisation via an industrial ethernet network.

Here the integration of all process technology servers and operating stations takes place. This network is designed as an industrial ethernet network.

The process control system allows for monitoring and controlling the glass production process from a workplace equipped with monitors. All actions are effected in real time. All processes, including alarm management, can be monitored and controlled via this operator station. Graphical charts and historical data can also be retrieved at this station.

Level 1: Monitoring and visualising the central/decentralised systems as well as controlling and regulating the entire process. A major part of the control is managed by SPS and/or level 1 automations.

Level 2: The main function is to optimise the operation of level 1 and to output actuating variables and control points

Level 3: Serves for planning, quality control and documentation

The collected data is processed and sent to higher-level production planning software via interfaces. These MES and/or ERP systems can be integrated in a user-friendly way using an OPC solution.

The custom-built software controls all important parameters of melting, forming and annealing of the glass. For all critical processes, redundancy is implemented via a backup system. Switching between these systems can be performed “shock-free”.

Visualisation is available at operator stations and at decentralised operating panels.

All HORN® machines and equipment have a high level of automation, whereby maximum process and machine safety are achieved. Maintenance effort and routine activities are reduced to a minimum. This results in optimum production and longevity of the plants.

COOKIES

We use cookies to make it easier to use and to further improve our service.

If you have given us your consent, you can revoke it at any time in the data protection declaration.

COOKIES

Necessary

Necessary cookies help make a website usable by enabling basic functions such as page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

C3 Cookie

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| c3kie | hornglass.com | Saves the consent status of the user whether the cookie window should be displayed. | 180 days | HTTP Cookie |

Technical

Technichal cookies help to improve the user experience of the website. New functionalities will be enabled.

YouTube

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| yt-player-headers-readable | YouTube | Used to determine the optimal video quality based on the visitor's device and network settings. | Persistent | HTML Local Storage |

| VISITOR_INFO1_LIVE | YouTube | Tries to estimate the range of users on pages with built-in YouTube videos. | 179 days | HTTP Cookie |

| YSC | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Session | HTTP Cookie |

| yt.innertube::nextId | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Persistent | HTML Local Storage |

| yt.innertube::requests | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Persistent | HTML Local Storage |

| ytidb::LAST_RESULT_ENTRY_KEY | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-cast-available | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-cast-installed | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-connected-devices | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-device-id | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-fast-check-period | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-session-app | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-session-name | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

Advertisement

Advertisement cookies allow our advertising partners to show you ads that fit your interests.

TikTok

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _ttp | TikTok | Used to store a unique user ID. | 1 year | HTTP Cookie |

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _fbp | Used to store and track visits to websites. | 3 months | HTTP Cookie |

Statistics

Statistics cookies help website owners understand how visitors interact with websites by collecting and reporting information anonymously.

Google Tag Manager

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _ga | Google Tag Manager | Registers a unique ID that is used to generate statistical data on how the visitor uses the website. | 2 years | HTTP Cookie |

| _ga_ | Google Tag Manager | Collects data on how often a user visited a website, as well as data on the first and last visit. Used by Google Analytics. | 2 years | HTTP Cookie |

Microsoft Clarity

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _clck | Microsoft | Persists the Clarity User ID and preferences, unique to that site is attributed to the same user ID. | 1 year | HTTP Cookie |

| _clsk | Microsoft | Connects multiple page views by a user into a single Clarity session recording. | 1 year | HTTP Cookie |

| CLID | Microsoft | Identifies the first-time Clarity saw this user on any site using Clarity. | 1 year | HTTP Cookie |

| ANONCHK | Microsoft | Indicates whether MUID is transferred to ANID, a cookie used for advertising. Clarity doesn't use ANID and so this is always set to 0. | 1 year | HTTP Cookie |

| MR | Microsoft | Indicates whether to refresh MUID. | 1 year | HTTP Cookie |

| MUID | Microsoft | Identifies unique web browsers visiting Microsoft sites. These cookies are used for advertising, site analytics, and other operational purposes. | 1 year | HTTP Cookie |

| SM | Microsoft | Used in synchronizing the MUID across Microsoft domains. | 1 year | HTTP Cookie |