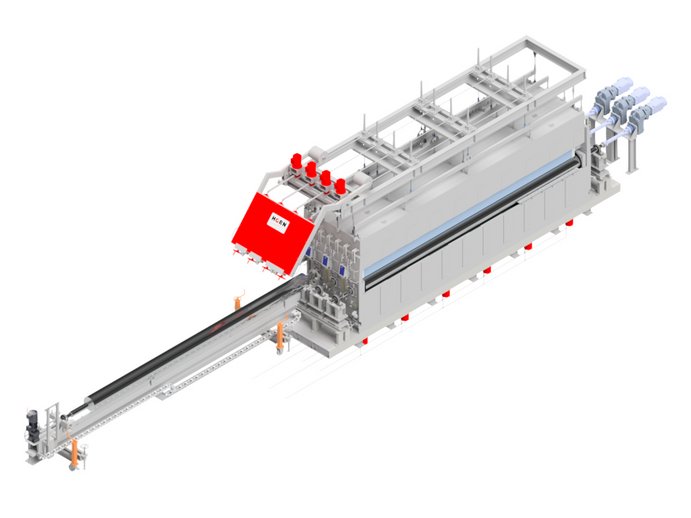

The dross box is the most important instrument for a smooth transfer of the glass ribbon from the tin bath into the annealing lehr. For this purpose the dross box needs to perform numerous important functions simultaneously:

The dross box consists of two main components: the dross box casing and the dross box hood with curtains.

The dross box casing is connected gas-tight to the tin bath casing by a special bolt system. The complete DB-Casing is insulated to reduce heat losses to a minimum. Special sealing of the lift-out rollers (LOR) ensures a maximum atmosphere tightness of the bottom part. The casing is connected to the strong base-frame in such a way that they can move freely relative to each other, thus ensuring a controlled heat expansion without deformation. Special design and welding procedures ensure minimal to no heat deformations during heat-up and operation.

The individual LOR bearing system works independent of the casing and is adjustable within ± 25 mm. No water or oil cooling is required. An individual drive system for lift-out rollers is available as an option. A special pneumatically controlled graphite LOR-cleaning mechanism serves for perfect sealing and cleaning of the three LORs. The pressure can be adjusted on a control panel within seconds. The graphite blocks are reliably placed in a solid cast-iron U-beam and are quickly and easily exchangeable. Hot swapping of the lift-out rollers under a running glass ribbon is possible.

The dross box hood is connected gas-tight to the tin bath roof. The hood suspension is installed on the same supporting steel structure as the roof, allowing for heat expansion of the roof. The hood is fully insulated to reduce heat losses. There are four curtains inside the dross box hood, which are adjustable in height via motors. The curtains serve to minimise oxygen influx into the tin bath. For this purpose the curtains are positioned as close to the glass ribbon as possible. Curtain positioning can be monitored through the inspection window in the side sealing.

Operation via hand wheels is also possible in case of power or control failure. The curtains above the glass ribbon and the lift-out rollers below it form individually sealed chambers, which creates a labyrinth sealing and reduces atmosphere and heat losses to a minimum.

The glass ribbon is lifted from the liquid tin in the tin bath by means of the lift-out rollers (LOR) and transported into the annealing lehr through the dross box. This design can accommodate various types of lift-out rollers (steel, ceramic, ceramic coated). The lift-out rollers are adjustable in height, so they can adapt optimally to the required properties of the glass ribbon.

The lift-out curve depends on factors like glass temperature and glass thickness. Therefore the adaptability of the lift-out rollers is essential. The lift-out rollers can be driven by the mechanical drive system of the annealing lehr or optionally by an independent drive system. With an independent drive system each lift out roller can be driven individually.

Various injection points for N2/SO2, as well as temperature/pressure sensors, are located on the casing and hood. The nitrogen for the casing is preheated in the tin bath exit lip before injection. All parts of the dross box are designed to the customer’s specific requirements in order to improve glass quality and yield.

COOKIES

We use cookies to make it easier to use and to further improve our service.

If you have given us your consent, you can revoke it at any time in the data protection declaration.

COOKIES

Necessary

Necessary cookies help make a website usable by enabling basic functions such as page navigation and access to secure areas of the website. The website cannot function properly without these cookies.

C3 Cookie

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| c3kie | hornglass.com | Saves the consent status of the user whether the cookie window should be displayed. | 180 days | HTTP Cookie |

Technical

Technichal cookies help to improve the user experience of the website. New functionalities will be enabled.

YouTube

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| yt-player-headers-readable | YouTube | Used to determine the optimal video quality based on the visitor's device and network settings. | Persistent | HTML Local Storage |

| VISITOR_INFO1_LIVE | YouTube | Tries to estimate the range of users on pages with built-in YouTube videos. | 179 days | HTTP Cookie |

| YSC | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Session | HTTP Cookie |

| yt.innertube::nextId | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Persistent | HTML Local Storage |

| yt.innertube::requests | YouTube | Registers a unique ID to keep statistics on which videos from YouTube the user has seen. | Persistent | HTML Local Storage |

| ytidb::LAST_RESULT_ENTRY_KEY | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-cast-available | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-cast-installed | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-connected-devices | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-device-id | YouTube | Saves the user's video player settings with embedded YouTube video. | Persistent | HTML Local Storage |

| yt-remote-fast-check-period | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-session-app | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

| yt-remote-session-name | YouTube | Saves the user's video player settings with embedded YouTube video. | Session | HTML Local Storage |

Advertisement

Advertisement cookies allow our advertising partners to show you ads that fit your interests.

TikTok

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _ttp | TikTok | Used to store a unique user ID. | 1 year | HTTP Cookie |

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _fbp | Used to store and track visits to websites. | 3 months | HTTP Cookie |

Statistics

Statistics cookies help website owners understand how visitors interact with websites by collecting and reporting information anonymously.

Google Tag Manager

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _ga | Google Tag Manager | Registers a unique ID that is used to generate statistical data on how the visitor uses the website. | 2 years | HTTP Cookie |

| _ga_ | Google Tag Manager | Collects data on how often a user visited a website, as well as data on the first and last visit. Used by Google Analytics. | 2 years | HTTP Cookie |

Microsoft Clarity

| Name | Provider | Purpose | Expiration | Type |

|---|---|---|---|---|

| _clck | Microsoft | Persists the Clarity User ID and preferences, unique to that site is attributed to the same user ID. | 1 year | HTTP Cookie |

| _clsk | Microsoft | Connects multiple page views by a user into a single Clarity session recording. | 1 year | HTTP Cookie |

| CLID | Microsoft | Identifies the first-time Clarity saw this user on any site using Clarity. | 1 year | HTTP Cookie |

| ANONCHK | Microsoft | Indicates whether MUID is transferred to ANID, a cookie used for advertising. Clarity doesn't use ANID and so this is always set to 0. | 1 year | HTTP Cookie |

| MR | Microsoft | Indicates whether to refresh MUID. | 1 year | HTTP Cookie |

| MUID | Microsoft | Identifies unique web browsers visiting Microsoft sites. These cookies are used for advertising, site analytics, and other operational purposes. | 1 year | HTTP Cookie |

| SM | Microsoft | Used in synchronizing the MUID across Microsoft domains. | 1 year | HTTP Cookie |